- +91 9549933444

- info@rmrglobal.co.in

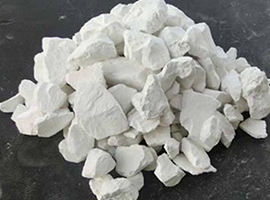

Limestone

Limestone is considered to be a stone ingrained with geological and historical memories. It is a specimen of quality architectural expression as it possess hardness and resistance to harsh climate, hence, making it suitable for exterior and interior designing applications. Many landmarks across the world, including the Great Pyramid and its associated complex in Giza and Egypt and also ancient American sculptors were made of limestone.

Limestone is a sedimentary rock composed primarily of calcium carbonate (CaCO3). It most commonly forms in clear, warm, shallow marine waters. It is usually an organic sedimentary rock that forms from the accumulation of shell, coral, algal, and fecal debris. It can also be a chemical sedimentary rock formed by the precipitation of calcium carbonate from lake or ocean water. These also contain at least a few percentage of other materials like quartz, feldspar, clay minerals, pyrite, siderite, and other minerals.

Limestone is available in various forms, texture & colour depending on the type of proportion and impurities. We supply premium quality limestone in different grades in domestic as well as international market at the most competitive prices. These are available in different colours from blue, brown to gray and pink tailoring to the client’s preferences.

• Cement Industry :

Limestone containing about 45% CaO and above is usually preferred for the manufacturing of cement. The proportion of Al2O3 + Fe2O3: SiO2 should be 1:2:5. Magnesia sulphur and phosphorus are regarding as most undesirable impurities

The presence of potash feldspar in a glaze or clay body has a more refractory effect on the ceramic surface compared to equivalent amounts of soda feldspar. They improve the strength, toughness, and durability of the ceramic body, promote colour brilliance and luster at most firing temperatures, and encourage specific colour results.

• Iron & Steel Industry :

Limestone is used in this industry both in the blast furnace to lower the temperature of melting and second to from calcium silicate by combining with silica of the iron ore, which comes out as slag. For this purpose good fluxing limestone low in acid constituents such as silica, alumina, sulphur and phosphorus is required. The limestone should be dense, massive, preferably fine grained, compact and non-fretting on burning.

• Chemical Industry :

The calcium carbide manufactures generally prefer lime containing 95% CaO (min.), not more than 3% SiO2, not exceed 2%.

• Sugar Industry :

In sugar industry lime is used for the clarification of juice form can be beets. Milk of lime 1% in volume of cane juice is added to pre-heated juice. Limestone to be used in sugar industry must be high in active lime (CaO S 80% min.) must be low in iron, alumina and silica, etc.

• Glass Industry :

Glass industry required high limestone (CaCO3: 94.5%) combine CaCO3 and MgCO3 should be 97.5%.

• Fertilizer Industry :

The latest use of limestone introduced in the country is in the manufacture of calcium ammonium fertilizers, limestone is used only as carrier. For this purpose limestone should contain MgCO3 + CaCO3 85% (min.) SiO2 5% (max.) and acid in-soluble 14% (max.)

• For production of Lime & Hydrated Lime

Limestone